Gear Hobbing Software

Nov 02, 2009 Tsugami Abile programming software. Rem Sales engineer designs a part using Tsugami Abile software.

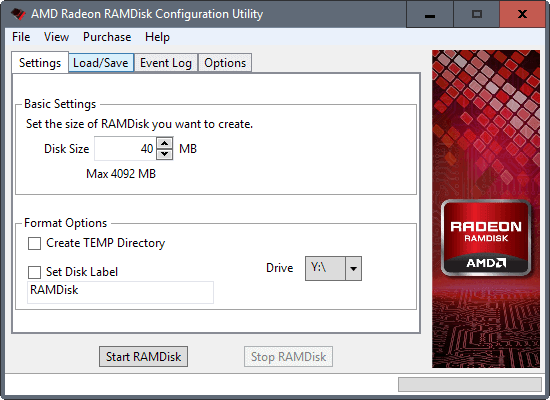

You may use it as fast, temporary storage for temporary data.  Move the browser cache to the RAM Disk, and never have to worry again about it filling up valuable disk space (as it is only available during that session).You may even install applications or games on the RAM Disk to benefit from faster loading times and less performance related issues while playing those games or using those apps. The core difference is that it is a virtual hard drive that uses RAM for storage. With it come notable differences born out of that: a RAM Disk is faster than hard drives, and the storage space that it offers is only available during the session unless the software supports the saving and loading of disk images.These traits make RAM Disks ideal for a lot of purposes.

Move the browser cache to the RAM Disk, and never have to worry again about it filling up valuable disk space (as it is only available during that session).You may even install applications or games on the RAM Disk to benefit from faster loading times and less performance related issues while playing those games or using those apps. The core difference is that it is a virtual hard drive that uses RAM for storage. With it come notable differences born out of that: a RAM Disk is faster than hard drives, and the storage space that it offers is only available during the session unless the software supports the saving and loading of disk images.These traits make RAM Disks ideal for a lot of purposes.

PCProCAM for Gear Hobbing is the latest in conversational CNC gear cutting software. Developed by NUM, as part of their NUMGear package, PCProCam for Gear Hobbing is a complete “off-the-shelf” programming solution for gear manufacturing.

How It Works

PCProCam’s user-friendly entry screens provide the machine operator with a comprehensive graphical programming approach that depicts the tool, the gear and associated setup data in a clear and concise manner. The operator does not have to use ISO programming; he or she simply fills in the data fields presented by the program. After completion of the data entry session, the program is automatically generated, stored, and it is ready for execution.

By using PCProCam for Gear Hobbing the user will be able to operate the machine even without prior knowledge of ISO code programming.

Included in PCProCam CNC Gear Cutting Software:

- User-Friendly Windows Based Interface

- Library of Tools (Straight Hob, Tapered Hob, or Milling Cutter)

- Automatic Hob Shift Management

- Helical Gears, Spur Gears or Worm Gears

- Hobbing Cluster Gears via an Unlimited number of Sequential Machining Cycles. (Any Combination)

- Vertical or Horizontal Machine Configuration

- Tooth Modifications ( Crown or Taper )

- Tooth Alignment to Another Gear on Same Shaft

- Radial Hobbing Cycle (Standard or Single Index)

- Radial Axial Hobbing Cycle (up to 4 cuts)

- Tangential or Diagonal Hobbing Cycle

- Integrated Context Sensitive Help File

- Machine Functions: Manual or Automatic Part Loading

- Machine Functions: Manual or Automatic Part Clamping

- Machine Functions: Manual or Automatic Tailstock

- Machine Functions: Manual or Automatic Coolant